Introduction to HDPE PLB Duct Pipes and Fittings

We have been offering a wide range of HDPE PLB Duct Pipes and Fittings such as pipe conduits, pipe ducts, HDPE Conduits, and PLB HDPE Ducts, that are manufactured from virgin Quality Raw Materials sourced from reliable vendors across the globe. Similarly, these pipe conduits, pipe ducts, HDPE conduits, and PLB HDPE Ducts are manufactured according to various Indian as well as International standards or can be customized as per the specifications of our clients.

Designed for Optical Fiber Networks

Furthermore, the HDPE PLB Duct is designed and engineered to house the sensitive nerves of Information technology i.e. optical fibers thus enabling information transfer across the globe. Available as per Indian and international Standards or Customer requirements most Suited for Pulling Optical Fibre cables (OFC), Telecom, Electrical Lines, etc.

Permanently Lubricated for Optimal Performance

Finally, apart from other HDPE pipes, ALEX offers permanently lubricated (PLB) Telecom ducts which have a layer of special compound on the inner side for smooth conveying of optical fiber cables with extremely low friction. In addition, we use a special compound for the production of PLB Ducts, which generally maintains the coefficient of friction between the inside of the HDPE duct and the outside of the inserted communication cable at 0.06 max.

HDPE PLB Duct Pipe

HDPE PLB Duct Pipes or High Density Polyethylene Permanently Lubricated Ducts are the high flow capacity ducts, which offer a very high quality option for the underground laying of optical fiber cable (OFC). These PLB HDPE Ducts are mainly used for the purpose of laying Optical Fiber Cable as underground conduits. The PLB Ducts are regarded with the bright future since the material in use, high density Polyethylene has several advantages. The future of these Pipes can be judged owing to these factors:

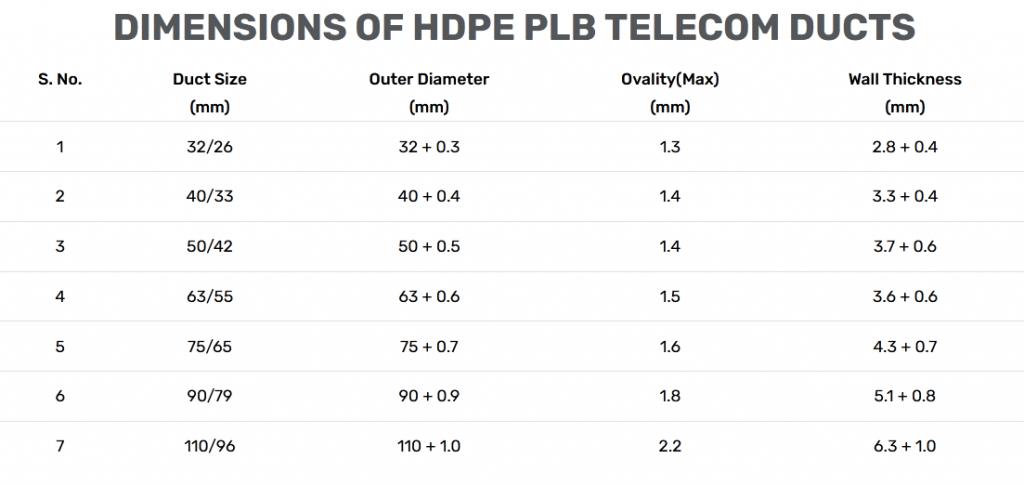

- Size Range: 32/26 mm, 40/33 mm, 50/42 mm.

- Color: Orange, Green, Brown, Blue, Black or as per Customers requirements.

- Available in Coils upto 1000 Meters Length.

- Material : Permanently lubricated HPDE Telecom Ducts are manufactured with the superior grade of High-Density Polyethylene materials. HDPE pipes manufactured meets all the requirements of TEC Specifications as well as IS 4984-1995.

- Lubrication.

- Permanently lubricated HDPE Telecom Ducts have special lubricated compound on Inner Side for Conveying Optical Fiber cables with extremely low friction. Coefficient of Friction between the inside of the HDPE Duct and the outside of the inserted communication cable does not exceed 0.06. Properties of Lubricant are Its strongly locked into HDPE. It has same physical/mechanical properties as HDPE except low Coefficient of Friction value which is less than 0.06. Its evenly distributed around the bore and along the length of duct. Does not react with water, hence it is possible to clean the duct by water stream in case of any obstruction/accident. Have same frictional properties during life of the duct.

- Product Applications.

- HDPE Ducts are suitable for installation in the field dirt trenches, under sidewalks, roads, within communication networks, between communication centers and between cities. They can also be used in branch networks between cells, distribution cabinets, poles, in walls and within subterranean networks of homes, allowing the insertion of optical or copper communication cables.

- All the compatible fabricated fittings are offered to address system requirements.

- The Ducts manufactured as per TEC Specification G/CDS-08/02, Nov 2004 Á ISO Standards.

- Available Orange, Yellow, Red, Purple, Grey, Green, Blue & Black Colours for easy identification.

- Offered in coils of 200, 500 & 1000 mtrs. Length thus reducing the number of joints in network which enables to reduce the cost & time of installation. Other coil lengths are availbale as per customers specifications.

- Plastic Couplers to join two Duct lengths air tight & water tight.

- End plugs to seal Duct ends prior to the installationof cable.

- Cable sealings plugs to seal Ducts ends after insertion of the cable.

- End caps mad of hard rubber, fitted on both the ends of ducts coil upon manufacturing.